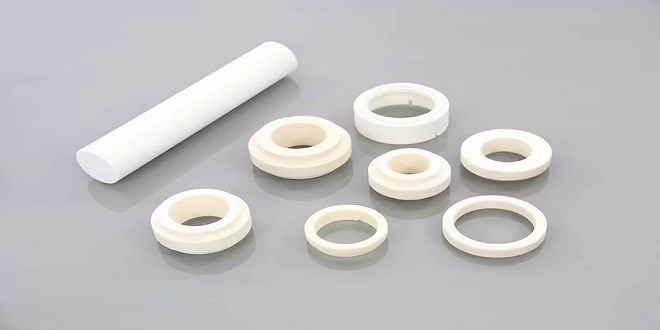

Why Aluminum Oxide Ceramic is the Material of Choice for High-Tech Industries – JUNTY Explains

Aluminum oxide ceramic, also known as alumina or Al2O3, has been widely used in high-tech industries for its exceptional properties. In this article, JUNTY explains why aluminum oxide ceramic is the material of choice for mechanical seal parts and other industrial applications.

Desirable Properties of Alumina

Historically, alumina has been the most popular and economical engineering ceramic material. It exhibits several desirable qualities, including good hardness, excellent wear resistance, high strength and stiffness, good thermal stability, and nearly chemical inertness. These properties make alumina an ideal material for use in mechanical seals, bearings, cutting tools, and other high-tech applications.

Chemically Inert

One of the primary reasons that aluminum oxide ceramic is so prevalent in high-tech industries is its chemical inertness. The material does not react with other substances or change chemically under extreme conditions. As a result, it can be applied to nearly any mechanical seal without the risk of corrosion or degradation over time. This makes it an ideal choice for use in harsh environments where other materials might fail.

Wear Resistance

Aluminum oxide ceramic is also known for its exceptional wear resistance. This property makes it ideal for use in mechanical seal parts subjected to high friction and wear. Compared to other materials, alumina wears much slower, which means it lasts longer and requires less maintenance over time. This property makes it suitable for use in demanding applications such as aerospace, manufacturing equipment, and other industrial machinery.

Thermal Stability

Another advantage of using aluminum oxide ceramic is its excellent thermal stability. The material can withstand high temperatures without losing its structural integrity or experiencing significant changes in its physical properties. Alumina is an ideal choice for applications involving extreme heat, such as in aerospace or manufacturing equipment. This property makes it an excellent choice for high-tech applications where temperature resistance is essential.

Purity Ranges

JUNTY understand that different industries have unique needs and requirements when it comes to their mechanical seals. That’s why they offer aluminum oxide ceramic in purity ranges from 95% to 99.5%. The higher the purity level, the greater the material’s strength and durability. They can also manufacture alumina in different colors to meet the diverse needs of our clients.

Conclusion

In conclusion, aluminum oxide ceramic is an excellent choice for high-tech industries due to its exceptional properties. Its chemical inertness, wear resistance, thermal stability, and strength make it an ideal material for use in mechanical seal parts and other industrial applications. JUNTY provides high-quality and good wear-resistance mechanical seal parts made of aluminum oxide ceramic, which can be manufactured to meet the diverse needs of our clients.